About Us

BIQI Digital Indutry LTD. (hereinafter referred to as "BIQI Digital") was established in 2021, with the vision of "making manufacturing smarter" and the mission of "building an intelligent manufacturing platform for large enterprises, allowing small and medium-sized enterprises to enjoy the digital dividend of intelligent manufacturing, and promoting the high-quality development of digital transformation of the industry". It is committed to providing intelligent manufacturing digital transformation and upgrading solutions for the metal manufacturing industry. BIQI Digital based on BIQI brand more than 20 years of R & D iteration, platform construction, product delivery, operation and maintenance precipitation, BIQI digital has quickly become a small number of professional manufacturers with the full value chain information platform product development and delivery and smart factory overall planning and implementation capabilities.

On the road of intelligent manufacturing transformation and upgrading, we use advanced technical means, such as AI, 5G, IOT, big data, digital twins, etc., to deeply integrate information technology (IT), operational technology (OT), digital technology (DT), and comprehensively promote the realization of intelligent manufacturing. Through a goal-oriented methodology, we are committed to providing professional and comprehensive services throughout the transformation process, from the initial consultation phase to the system implementation and technical support. The customer base includes local enterprises, as well as top 100 companies at home and abroad, and the international platform guarantees the international business promotion of BIQI smart digital solutions.

Data is the engine: Powering a smart manufacturing edge appliance

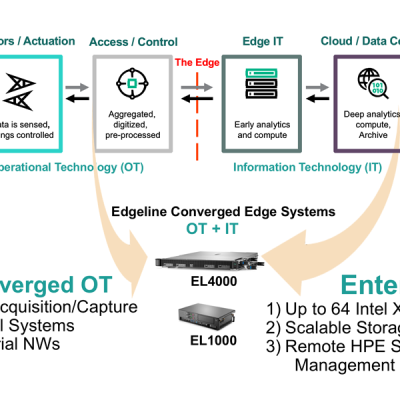

Data is the engine that will drive adoption of Industry 4.0, an industrial revolution for automating production and producing better products. Yet several factors prevent manufacturers from fully exploiting operational data.

Traditional operational technology (OT) architectures tend to be monolithic and difficult to upgrade. And although today’s production machines generate terabyte-class volumes of IoT sensor data, it often remains siloed in non-standard formats. In addition, analytical insights require OT to be integrated with IT systems such as enterprise resource planning (ERP) and product lifecycle management. Manufacturers may lack personnel for this work.

Another challenge is where to process the data. Enterprises typically favor central processing in a data center or the cloud. But because insights into production are needed instantly, central processing adds latency. By the time OT data is sent and analyzed, its usefulness could have expired.

The first is the automatic transformation represented by the mechanization and automatic control of the production line; The second is the information upgrade represented by the enterprise information system from decentralization to unification.

Achieve internal personnel management coordination, production and operation coordination and management coordination; Third, the data is the core of the original method and model digital precipitation

Reuse of applications (industrial software) is the main task of digital integration.

Digital industrialization emphasizes the control of industrial chain, the overall improvement of synergy, and the development of industrial clusters: first, data is the core, linking "research, production, supply and marketing services"

Full factor data to achieve the product life cycle of fine management, quality molding brand, enhance the industrial chain control; Third, take business as a starting point to strengthen production

The synergy between the upper and lower levels of the industry chain, internal and external coordination, and factor coordination, enhance the synergy of the industrial chain, and enhance the overall competitiveness; The third is to drive standards, promote the development of industrial clusters and industrial clusters, and achieve stable and efficient allocation of social resources.

Data intelligence emphasizes the role of AI in accelerating the fundamental change of manufacturing production methods and enterprise forms, which is mainly divided into quality optimization and extension of value-added

Two categories of services: First, in the quality control link, through "data +AI" to improve the quality and efficiency of key processes; The third is to play with data and AI throughout the extension

The value breakthrough of the domain covers the value reconstruction of e-commerce, logistics, finance and other fields.

We will focus on key areas and scenarios combined with AI to create cloud-native applications and incubate industrial software. At the same time, play big industry

Data value catalyzes digital supply chain and industrial chain, integrates cloud, network and digital simultaneously, and builds new industrial infrastructure.

After combining real-time IoT data from factory stations with product information from the SAP ERP system, BIQI analyzes the data in near-real time. As a result, managers can quickly visualize the status of production and gain insights into how to improve.

Bringing AI, application integration and the hybrid cloud into their plants can help other producers become smarter manufacturers. It’s an important step toward fulfilling the promise of Industry 4.0.

Meet The Team

Lucas Schultz

Ara Dare

Dimitri Abernathy

Discover all BIQI GITAL Features

If you know more about our business, please feel free to contact us